Introduction

Laser cutting is a versatile and efficient manufacturing process that allows for the creation of intricate and detailed designs with precision and accuracy. If you’re considering laser cutting for your custom project, you might be wondering how to get started. In this guide, we’ll walk you through the design process, from concept development to laser cutting, to help you bring your vision to life.

Step 1: Concept Development

The first step in the design process is to develop a clear understanding of your project’s requirements and goals. Begin by sketching out your ideas and gathering any relevant reference materials or inspiration. Consider the following questions:

What is the purpose or function of your design?

What materials would be most suitable for your project?

What are the dimensions and tolerances required for your design?

Are there any specific aesthetic or functional features you’d like to incorporate?

Step 2: Consultation with a Laser Cutting Expert

Once you have a clear vision for your project, it’s time to consult with a laser cutting expert. They can help you refine your design, choose the most appropriate material, and determine the best approach for laser cutting your project. Some key aspects to discuss during the consultation include:

The feasibility of your design, including any potential challenges or limitations.

Material selection, considering factors such as durability, cost, and appearance.

The optimal laser cutting settings, such as cutting speed and power, to achieve the desired results.

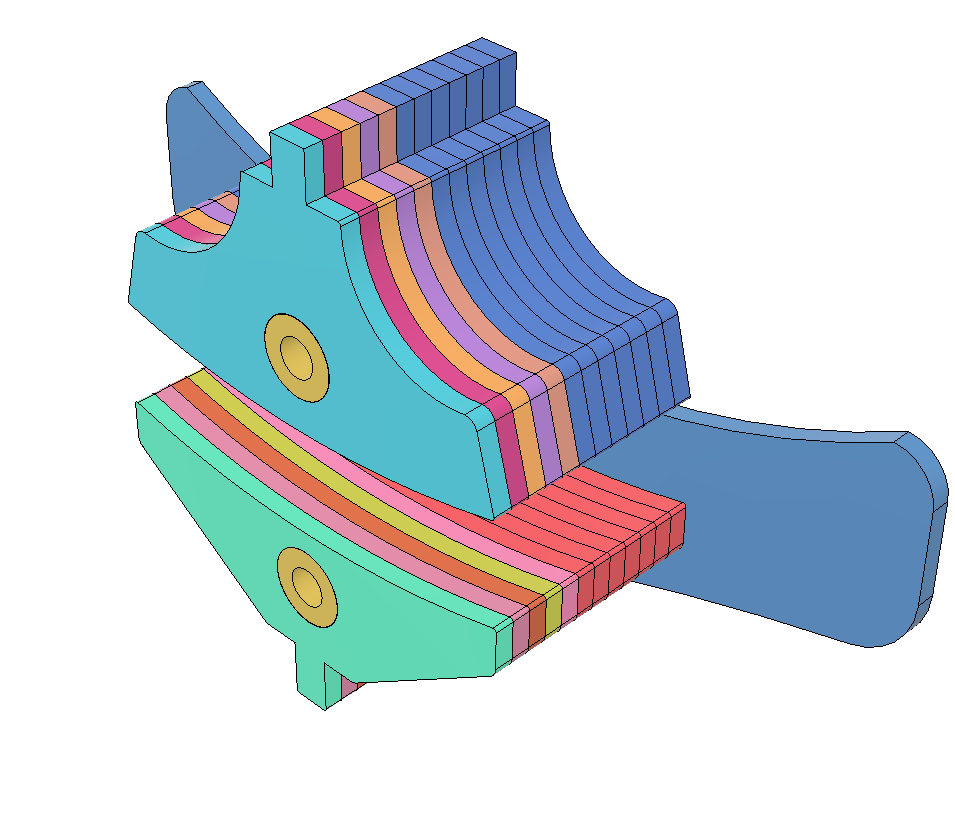

Step 3: Create a Digital Design File

After consulting with the laser cutting expert, you’ll need to create a digital design file that can be used to program the laser cutter. This typically involves using a vector-based design software, such as Adobe Illustrator or CorelDRAW, to create a 2D representation of your design. Be sure to:

Use clean, precise lines and curves to define your design elements.

Set the appropriate line colors and thicknesses to indicate cut lines, engraving lines, and any other laser operations.

Save your file in a format that is compatible with the laser cutting software, such as DXF, AI, or SVG.

Step 4: Design Review and Approval

Before moving forward with laser cutting, it’s essential to review your digital design file carefully. Check for any errors, inconsistencies, or potential issues that may affect the final outcome of your project. Once you’re satisfied with your design, submit it to the laser cutting expert for their review and approval. They may provide feedback or suggestions to optimize your design for laser cutting.

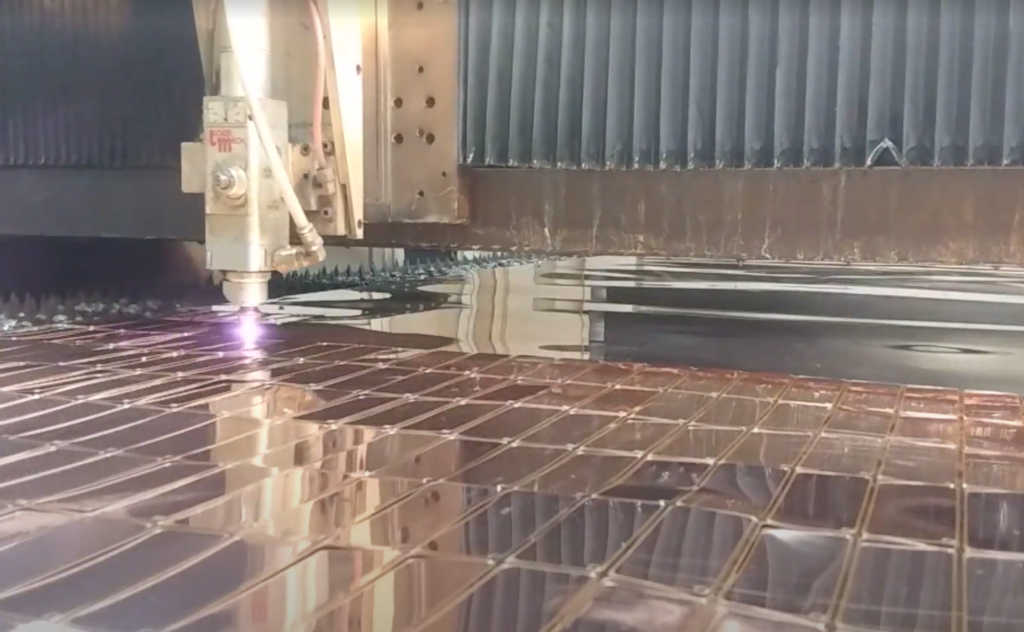

Step 5: Material Preparation and Laser Cutting

After your design has been approved, the laser cutting expert will prepare the chosen material for cutting. This may involve cleaning the surface, applying any necessary protective coatings, or prepping the material for optimal cutting performance. The digital design file is then loaded into the laser cutter, and the cutting process begins. The laser cutter will follow the design file’s specifications to create your custom project with precision and accuracy.

Step 6: Post-Cutting Inspection and Finishing

Once the laser cutting is complete, your project will be inspected for quality and accuracy. The laser cutting expert will check for any imperfections or inconsistencies and make any necessary adjustments or corrections. Depending on your project’s requirements, additional finishing processes may be required, such as deburring, polishing, or painting.

Step 7: Delivery and Installation

After the post-cutting inspection and any required finishing processes, your custom project is ready for delivery or installation. The laser cutting expert will package your project carefully to ensure it arrives safely and without damage. If your project requires installation, they can provide guidance or assistance to ensure the final result meets your expectations.

Conclusion

The process of designing and laser cutting a custom project may seem daunting, but by following these steps and working closely with a laser cutting expert, you can bring your vision to life with precision and accuracy. From concept development to post-cutting inspection, each step of the process is crucial to ensure a successful outcome.

Remember that effective communication and collaboration with your laser cutting expert are essential throughout the process. They can provide valuable insights and recommendations to help optimize your design and ensure the best possible results. By keeping an open line of communication and being receptive to feedback, you can make informed decisions and create a custom project that meets your specific requirements and goals.

In conclusion, laser cutting is an incredibly versatile and efficient manufacturing process that allows for the creation of intricate and detailed designs. By following a structured design process and working closely with a skilled laser cutting expert, you can turn your ideas into a tangible, high-quality product. Whether you’re working on a small-scale personal project or a large-scale commercial endeavor, laser cutting is a powerful tool that can help bring your vision to life.

Sales@traxda.com 888-660-5892